For more information about DLC coatings and how you can best use them, contact us!

DLC (Diamond-Like Carbon) coatings are carbon-based coatings that provide solutions for abrasion, friction, and chemical aggression across a wide range of applications.

They can be produced using different technologies (PVD, CVD, PECVD), with each technique imparting slightly different properties to the deposited carbon.

At ANTEC Finiture S.r.l., we utilize PECVD technology, which allows low-temperature deposition, enabling the coating of metals and alloys that could otherwise soften or deform at high temperatures.

Additionally, PECVD ensures the coating remains uniform in its properties.

By hybridizing carbon with other elements, DLC coatings can achieve varied characteristics while maintaining high hardness and a low friction coefficient.

DLC Coating Structure & Variability

DLC coatings can be produced in different ways, leading to varying characteristics.

Depending on the ratio of sp3 (diamond-like) and sp2 (graphite-like) bonds, the film can be harder (more like diamond) or more lubricating and flexible (more like graphite).

DLC coatings are created by energizing carbon atoms through plasma, arc evaporation, sputtering, or ion beam methods.

This high-energy bombardment of the surface forms amorphous networks due to rapid deposition and material hybridization.

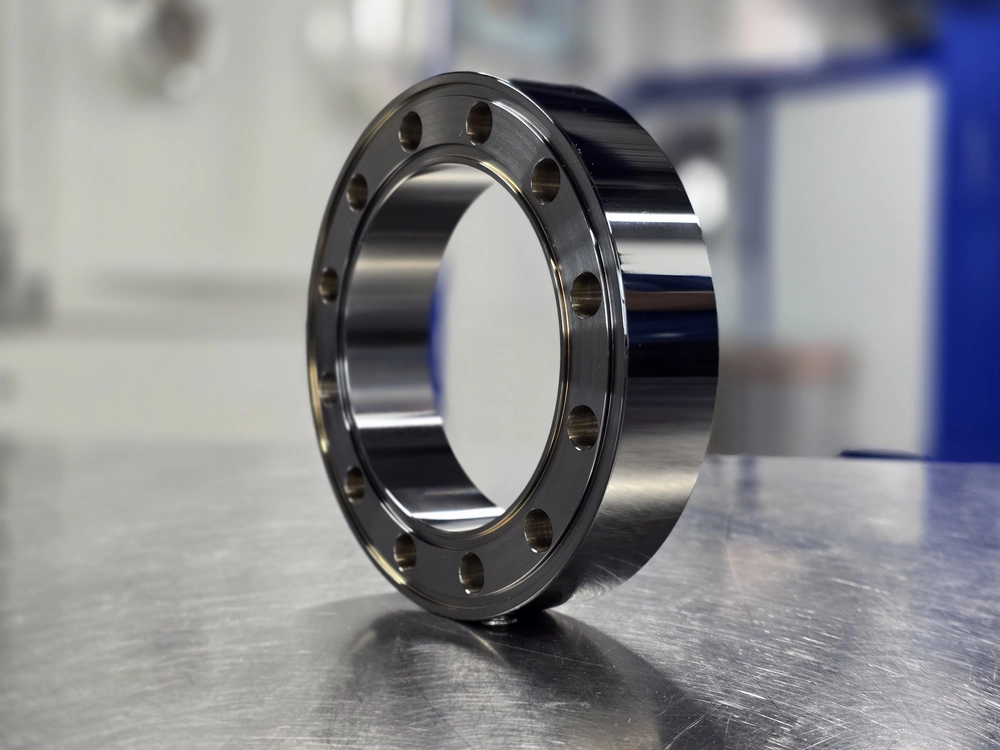

Without a crystalline structure, DLC lacks points of weakness, allowing it to be applied to complex geometries while remaining a highly durable film.

The hardest possible DLC is tetrahedral amorphous carbon (ta-C), which contains nearly 100% sp3 bonds.

However, ta-C is difficult to deposit, has poor adhesion, and can easily delaminate because the carbon-carbon bonds in the film are stronger than the bonds to the substrate.

To address these challenges, DLC coatings are often hybridized with hydrogen, metals, or additional sp2 bonds (graphite-like structure).

This improves deposition, adhesion, and flexibility, while also enhancing self-lubrication properties

DLC Coating Properties & Advantages

- High hardness

- Wear & abrasion resistance – all dlc coatings provide anti-wear and anti-abrasion protection.

- Low friction coefficient

- Scratch-resistant

- Gas impermeability

- Biocompatible

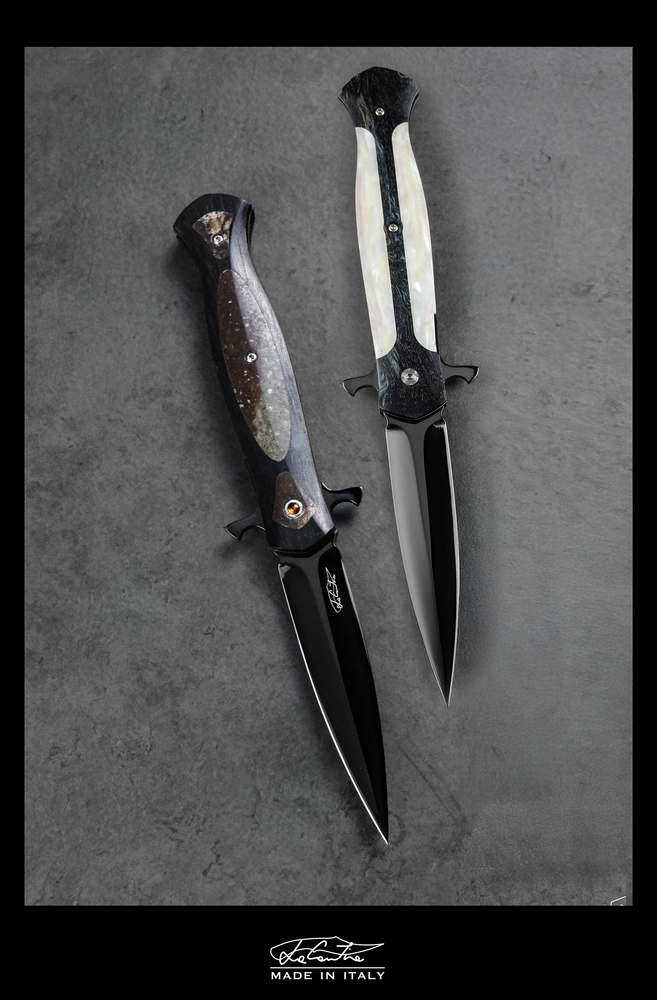

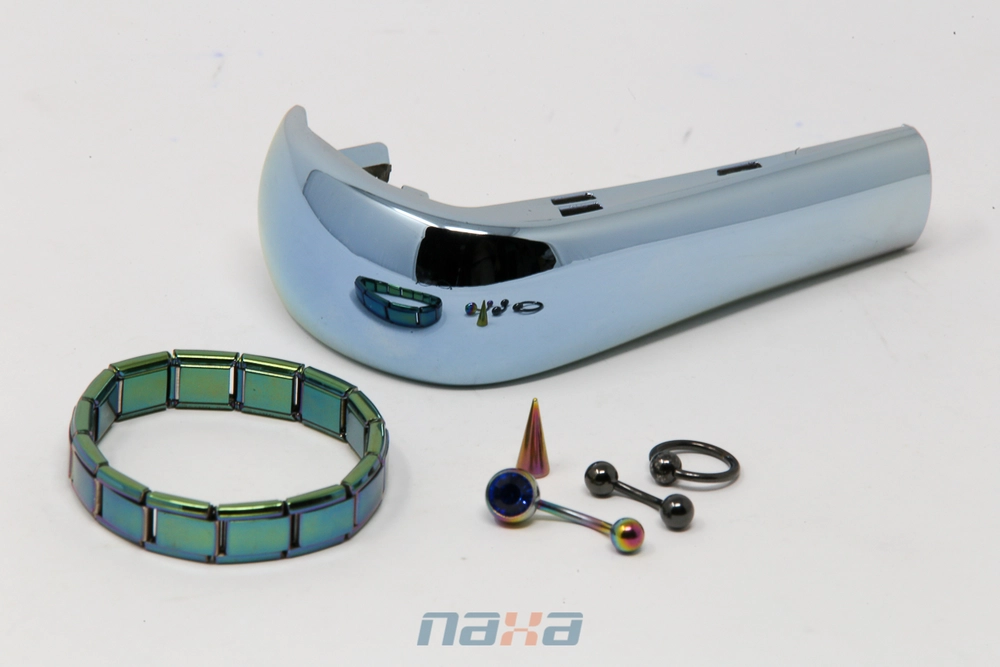

- Functional & aesthetic – dlc combines functionality with an appealing visual effect.

- Resistant to atmospheric, chemical, and organic agents

In Antec Finiture abbiamo sviluppato diversi coating DLC, per incontrare le esigenze del mercato:

DLC Coating Applications

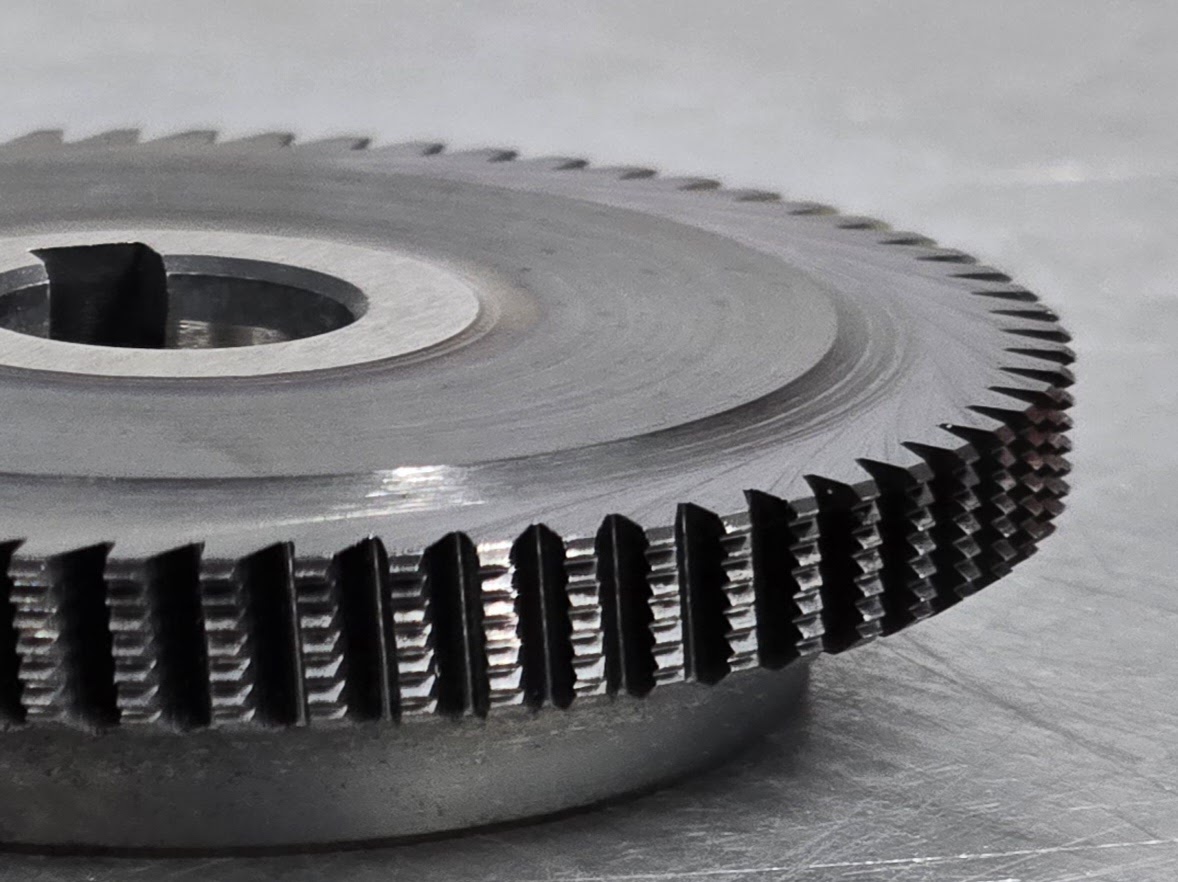

DLC coatings offer excellent wear resistance and self-lubrication.

Their biocompatibility and aesthetic appeal make them ideal for various industries.

Key Industry Applications:

- Automotive & racing: Enhances sliding performance for moving parts.

- Pumps & compressors: Ideal for pumps handling aggressive materials or valves regulating corrosive substances.

- Medical industry: Biocompatibility and black coloration make DLC suitable for surgical tools.

- Food processing: Prevents food residues from sticking to rollers, cutting blades, and surfaces, facilitating cleaning and reducing machine downtime.

- Textile industry: DLC treatments are widely used on textile machinery.

- Sporting equipment: High-end sports gear benefits greatly from DLC coatings. Applications include diving, marine, alpine skiing, cycling, shooting sports, and more.

- Fashion & luxury: Watches, belt buckles, jewellery, and accessories coated with DLC acquire a durable, total-black finish. 100% hypoallergenic for skin contact.

- Industrial machinery: DLC coatings increase machine speed and boost productivity.

Not all DLC coatings are the same. The same treatment can be achieved using different technologies and processes, resulting in varying characteristics. The coated parts play a crucial role, and knowing how to position them in the chamber is the first step in achieving a high-quality result.

Once the parts are positioned, various parameters can be adjusted to create the DLC coating: the type and percentage of precursor gases, altering the stoichiometry; the deposition rate; the applied power and bias values; as well as vacuum levels and process temperature. These variations allow for different chemical and physical properties, enabling DIATEC to be optimally adapted to each specific application while always keeping costs in mind.

An efficient DLC treatment is not simply the application of a basic substance, but the result of experience and expertise acquired over years of work. Antec Finiture S.r.l has been offering PECVD treatments since 1999. Our long-standing presence in the market is proof that we consistently provide the best solutions.

DLC Coating: Process Data & Characteristics

| Materials Used: | Argon, Nitrogen, Hydrogen, Acetylene, Silanes, Hexane |

| Max Process Temperature: | 150 °C |

| Minimum Thickness: | 1000 nm |

| Hardness Range: | min: 2500 max: 5000 Hv |

| Friction Coefficient: | As low as 0.02 (vacuum), 0.2 (humid air) |

| Surface Tension: | < 40 dyne |

| Thermal Conductivity: | approx 110 W/mk |

| Surface Interference: | < 0,05 Ra |

| Thermal Stability: | Up to 350 °C |

| Biocompatibility: | Yes (FDA, REACH, RoHS compliance) |

| Coating Type: | DLC (sp3 & sp2 carbon), hybridized with H or Si |

| Structure: | X-ray amorphous |

| Chemical Resistance: | Fully resistant to acids, alkalis, and solvents |

| Color: | Anthracite/Black or Shimmering Colored Variants |

DLC Coatings Developed by Antec Finiture

At Antec Finiture, we have developed multiple DLC coatings to meet market demands:

- DIATEC HC: Focuses on extreme hardness, with higher sp3 bonds, ensuring maximum wear resistance.

- DIATEC Hybrid: Prioritizes flexibility, with more sp2 bonds, lower hardness, and enhanced adhesion for complex geometries. o Offers a hard yet more elastic coating.

- DIATEC Deco: Optimized for aesthetics, offering a sleek technical black finish or shimmering colors (blue, red, green, purple, etc.).