For more information about DIATEC Hybrid and how you can use it effectively, contact us!

DIATEC Hybrid is a diamond-like carbon (DLC) coating hybridized with silicon.

This amorphous carbon and silicon plasma coating offers exceptional physical properties, making it ideal for multiple industries.

Proprietà del rivestimento DIATEC Hybrid

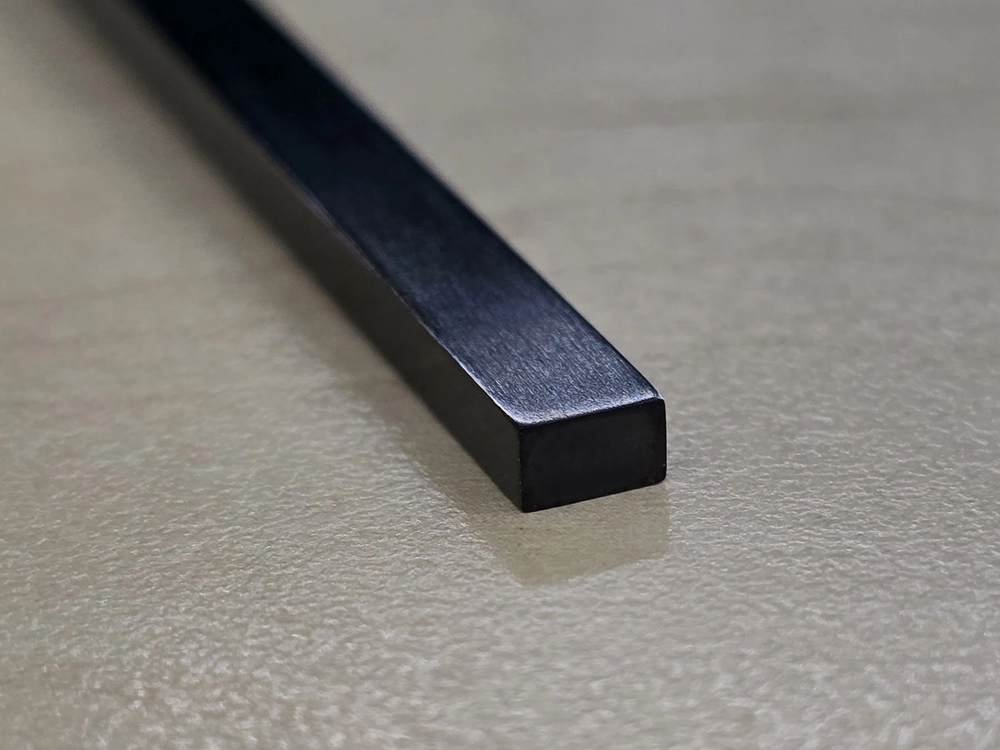

- HIGH HARDNESS DIATEC Hybrid achieves hardness levels around 1500 Hv. The presence of silicon-based interlayers provides elasticity, making the coating more flexible and deformable.

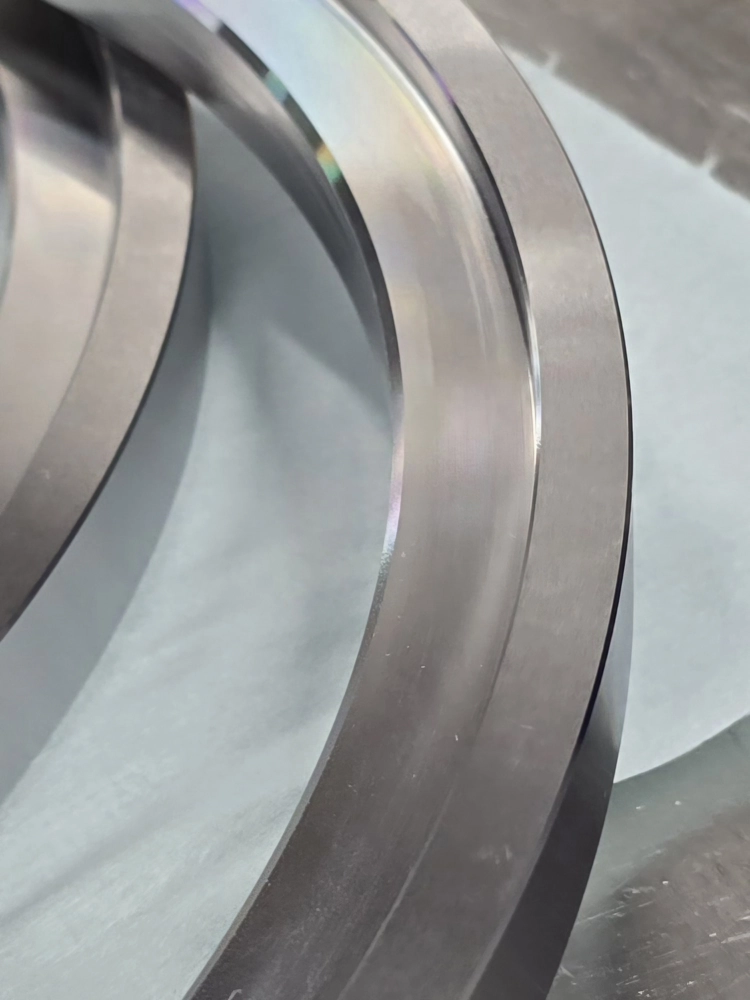

- SELF-LUBRICATING & HYDROPHOBIC: DIATEC Hybrid further reduces friction, requiring less effort and extending the life of components. Additionally, the final surface is hydrophobic, preventing water adhesion and deposit formation due to evaporation.

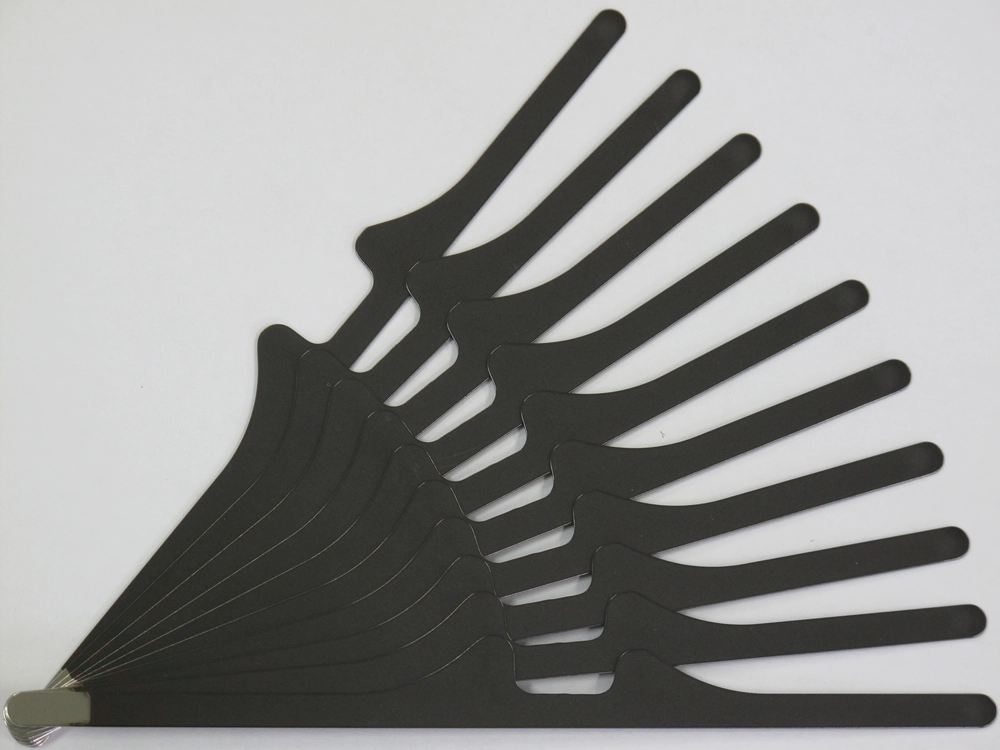

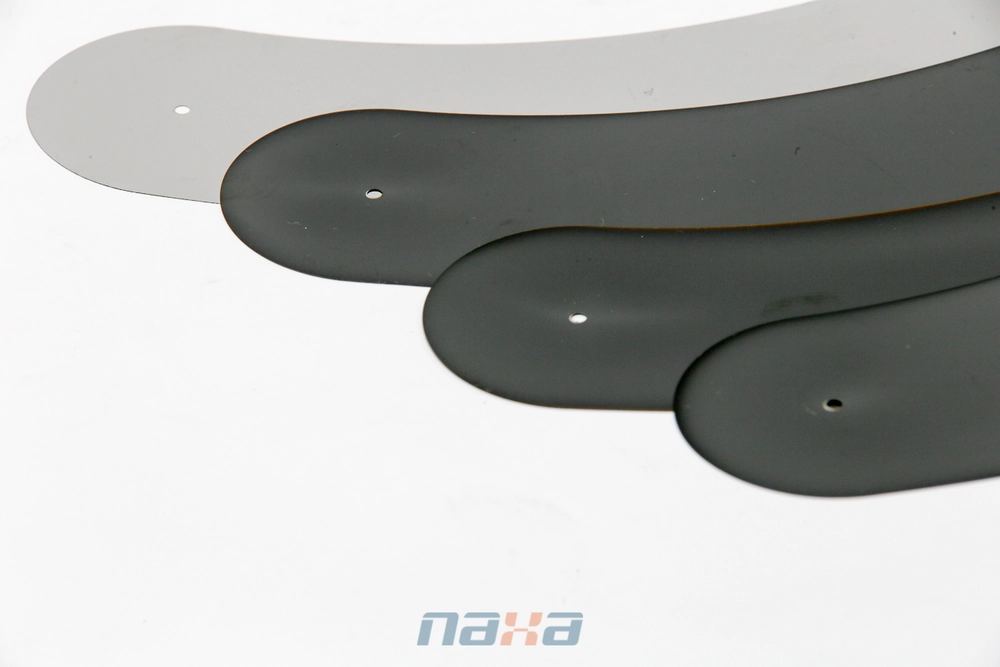

- TECHNICAL BLACK COLOR: DIATEC Hybrid provides a sleek black finish, making coated objects both functional and visually appealing.

- THERMAL STABILITY: DIATEC Hybrid can be applied at low temperatures (below 100°C) and maintains thermal stability up to 400°C.

- CHEMICAL RESISTANCE: PECVD technology ensures a homogeneous coating, preventing oxidation and corrosion attacks. Additionally, silicon-based interlayers enhance the barrier effect beyond standard DLC a:CH coatings.

- BIOCOMPATIBILITY & ENVIRONMENTAL FRIENDLINESS: Diamond-Like Carbon is biocompatible, non-cytotoxic, hypoallergenic, and completely inert, making it ideal for medical and food applications. The deposition process is clean, free of harmful emissions, and at ANTEC, it is powered by green energy, sourced from solar power and certified suppliers.

Not all DLC coatings are the same. The same treatment can be achieved using different technologies and processes, resulting in varying characteristics. The coated parts play a crucial role, and knowing how to position them in the chamber is the first step in achieving a high-quality result.

Once the parts are positioned, various parameters can be adjusted to create the DLC coating: the type and percentage of precursor gases, altering the stoichiometry; the deposition rate; the applied power and bias values; as well as vacuum levels and process temperature. These variations allow for different chemical and physical properties, enabling DIATEC to be optimally adapted to each specific application while always keeping costs in mind.

An efficient DLC treatment is not simply the application of a basic substance, but the result of experience and expertise acquired over years of work. Antec Finiture S.r.l has been offering PECVD treatments since 1999. Our long-standing presence in the market is proof that we consistently provide the best solutions.

DIATEC Hybrid: Technical Specifications

| Commercial Name: | DIATEC Hybrid© |

| Process Temperature: | Around a 100 °C |

| Thickness: | 500 – 4000 nm |

| Approx. Hardness: | 1200 Hv |

| Friction Coefficient: | 0.04 (in vacuum) |

| Thermal Conductivity: | 110 W/mk |

| Surface Interference: | < 0,05 Ra |

| Thermal Stability: | Up to 400°C |

| Biocompatibility: | Yes |

| Coating Type: | DIATEC HYBRID, a:CHSi |

| Structure: | X-ray amorphous |

| Chemical Resistance: | Unaffected by most acids and bases |

| Color: | Anthracite/Black |

DIATEC Hybrid: The Advantages

DIATEC Hybrid is a plasma coating with exceptional properties, designed to meet customer needs.

It is the ultimate anti-friction, scratch-resistant, wear-resistant, and anti-abrasion coating, especially suitable for metals and alloys sensitive to high temperatures.

Here are the 7 key advantages of DIATEC Hybrid:

- Excellent resistance to wear and abrasion.

- Low friction coefficient.

- Adjustable internal stress and elastic film.

- Advanced protection against atmospheric, chemical, and organic agents.

- Highly effective barrier against oxidation and corrosion.

- No alteration of surface roughness.

- Black carbon colour.

DIATEC Hybrid: Applications

DIATEC Hybrid is widely used in multiple industries, thanks to its versatility and high performance:

- Medical Sector: (Biocompatibility, low friction coefficient, wear resistance, and hydrophobicity—highly appreciated for surgical instruments.)

- Food Industry: (FDA approved, facilitates plant cleaning and reduces downtime.)

- Construction & Interior Design: (Facilitates cleaning, prolongs lifespan, prevents salt and limescale deposits—used for faucets, mixers, and glossy black design objects.)

- Printing & Extrusion: (Protects molds and punches from wear, facilitates object detachment during molding.)