Attachments

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

For more information about the SILkTOUCH © process and how you can use it to its full potential: Contact us!

SILkTOUCH © is a plasma process developed to make the surface of silicone objects silky and non-sticky to the touch.

It is a plasma post-curing process that interacts with the silicone of the object, crosslinking its surface so that it no longer feels sticky. This is not a deposition process, there is no addition of material. It is purely a surface modification achieved through exposure to plasma, UV radiation, and vacuum.

SILkTOUCH © is performed in a vacuum plasma environment, with process temperatures just slightly above room temperature. The objects are placed on specially designed supports, which are then introduced into a chamber evacuated to approximately 10⁻³ mbar and saturated with gas. These gases are then ionized to create a homogeneous plasma that can reach undercuts and cavities, reacting with the silicone surface to further crosslink it into what could be described as a semi-crystalline structure.

The SILkTOUCH © process does not alter the chemical composition of the objects, meaning they remain biocompatible and non-toxic if they already possessed those properties. Since no additional material is introduced, this treatment is particularly suitable for sensitive applications such as medical and baby care products, where health and non-toxicity are essential.

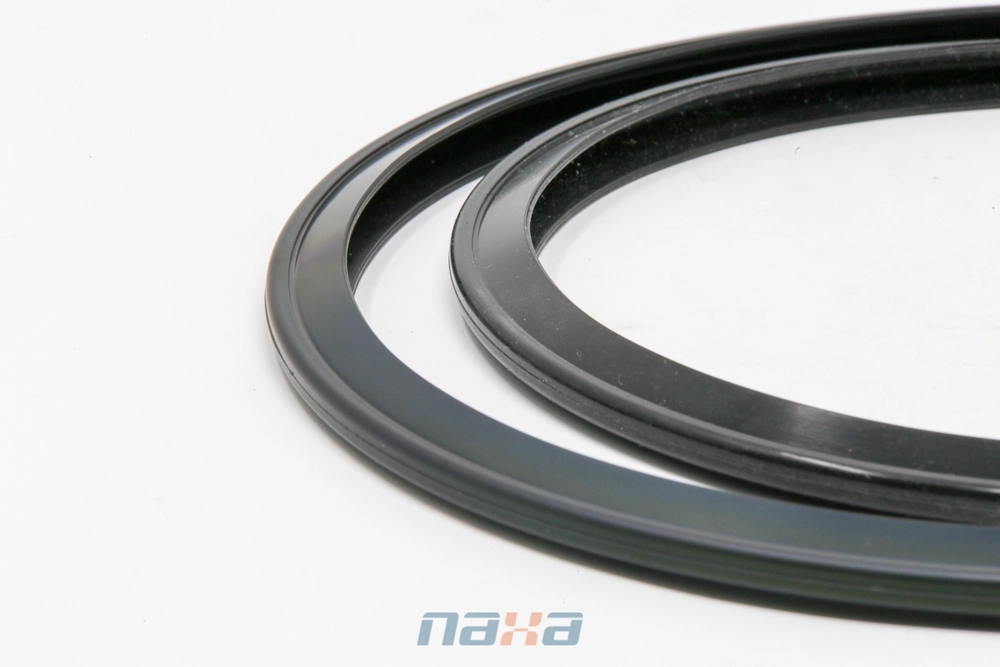

The treated surface may appear more matte visually but becomes silky to the touch and no longer sticky, preventing silicone objects from easily attracting dirt and dust.

An efficient plasma treatment is not simply the application of a basic substance but the result of years of expertise and technical knowledge. Antec Finiture S.r.l has been serving the market since 1999, gaining extensive experience in plasma PECVD coatings. Our long-standing presence in the industry is a testament to our ability to provide the best solutions, always guiding our customers toward the most suitable technologies for their needs, even when those technologies are not within our direct offering.

Technical Features of the Treatment

| Commercial name: | SILkTOUCH © |

| Gases Used: | Inert gases and oxygen |

| Maximum Process Temperature: | max. 60°C |

| Biocompatibility: | Yes |

| Treatment Type: | Vacuum plasma post-curing |

SILITEC Clean Plus©: Key Benefits

- No material deposition

- Reduces friction and eliminates sticking

- Does not alter the silicone's elastic properties

- Biocompatible and environmentally friendly

Applications of SILkTOUCH ©

- Baby care

- Medical

- Food industry

- Drinking water applications