For more information about SILITEC Seal© and how you can best use it, contact us!

SILITEC Seal© is a surface coating obtained through high-energy but low-temperature plasma.

This is a multi-layer silicon-based coating, transparent or semi-transparent, whose primary function is to limit or completely block the passage of undesired substances.

Whether it’s to increase the oxygen barrier or prevent the migration of chemical agents from the plastic materials of containers to their contents, SILITEC Seal is an effective solution.

Deposition method

SILITEC Seal is obtained through plasma enhanced (or assisted) chemical vapor deposition (PECVD or PACVD), with process temperatures that remain slightly above room temperature.

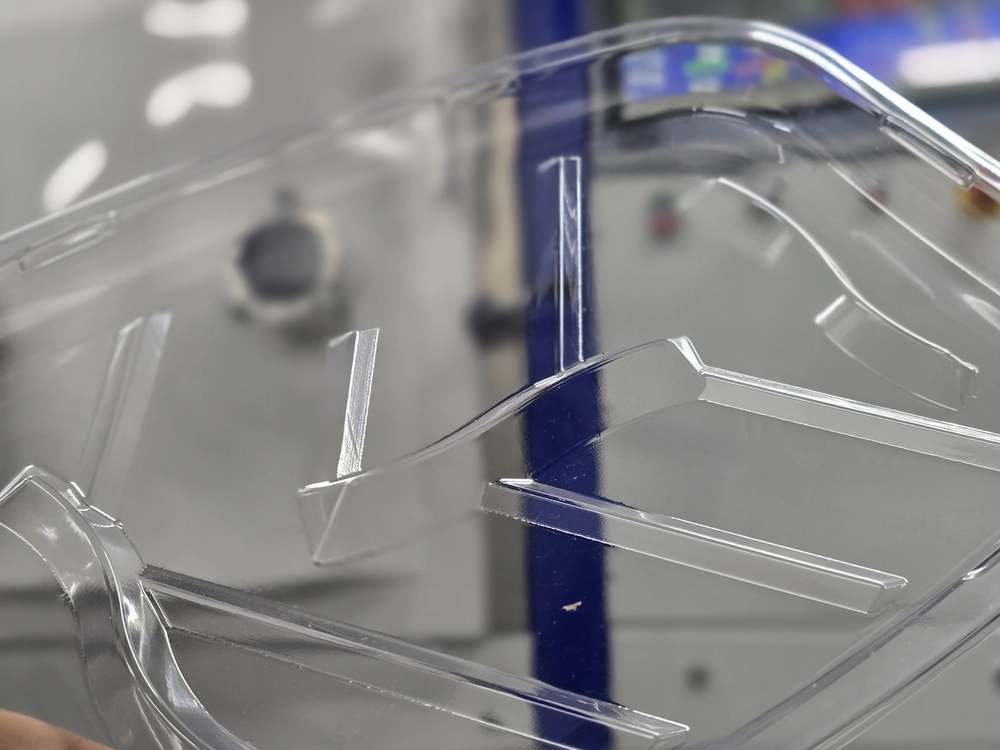

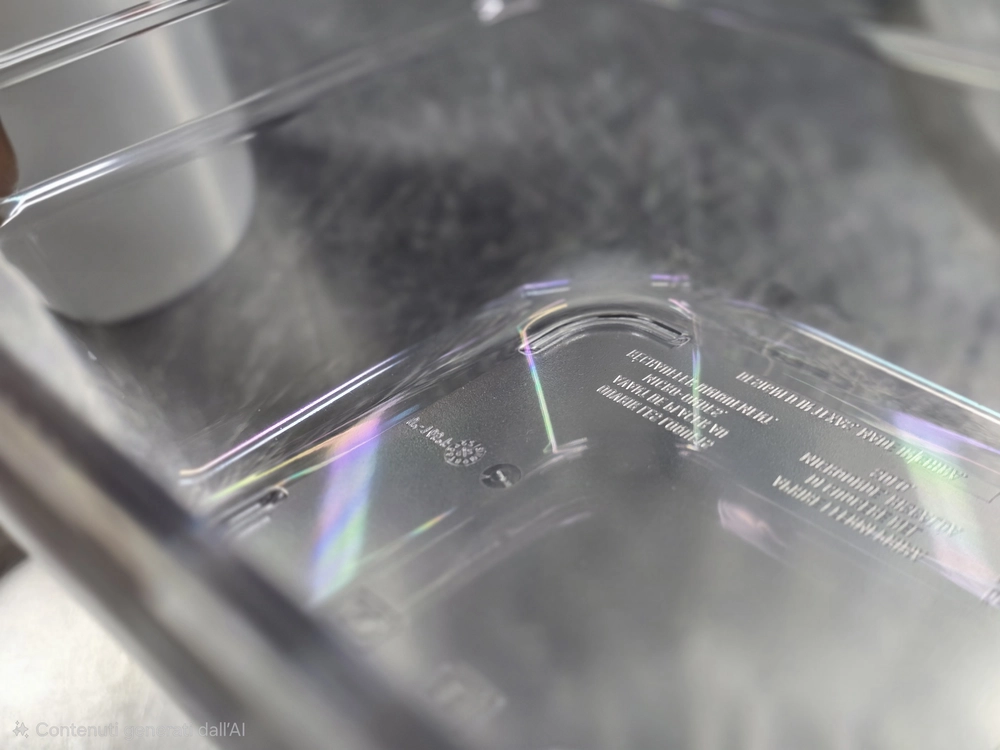

Objects are placed on specially designed supports and inserted into a vacuum chamber (at 10⁻³ mbar pressure), then saturated with gases, including silyl ethers and oxygen, which are ionized in a plasma state to form a homogeneous coating that can also penetrate undercuts and cavities.

The SILITEC Seal film bonds to the substrate through double bonds or plasma grafting, ensuring strong and long-lasting adhesion, which can only be altered mechanically.

As a result, objects become encapsulated in a highly effective barrier film, protecting them while preventing contamination of their surroundings.

Key features of SILITEC Seal©

- BIOCOMPATIBLE & NON-TOXIC SILITEC Seal is biocompatible and completely non-toxic. It is also bacteriostatic, meaning it prevents bacterial growth.

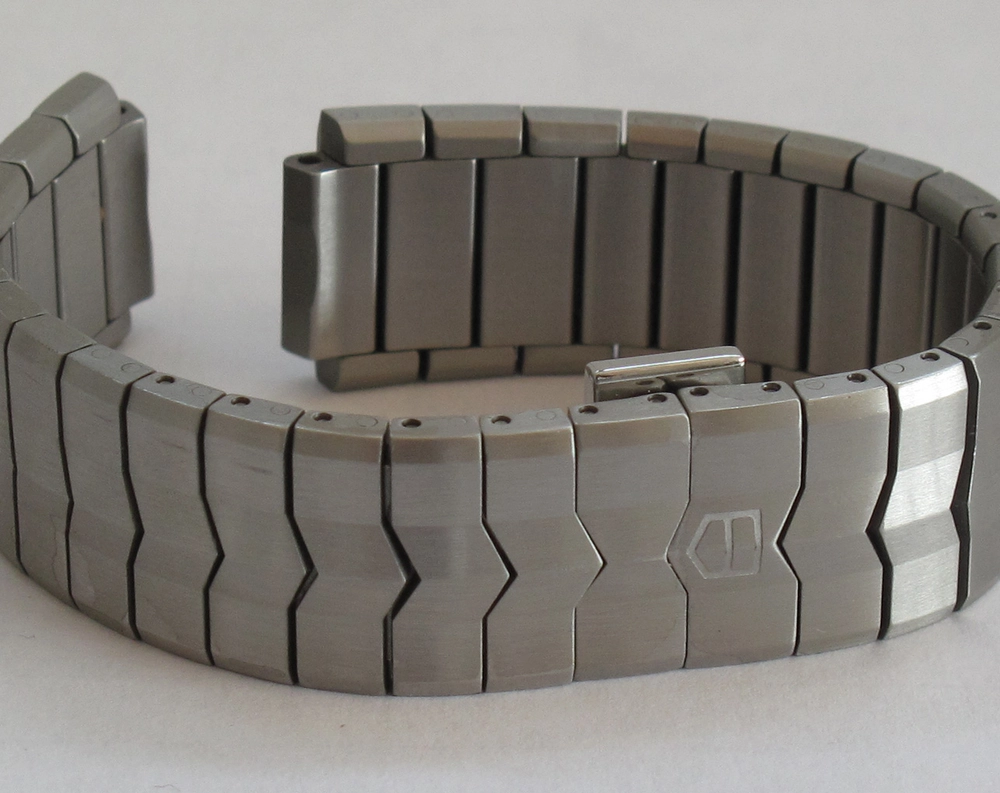

- PREVENTS METAL ALLERGIES SILITEC Seal can be applied to high-nickel alloys, allowing sensitive individuals to wear watches and jewelry without allergic reactions.

- CHROME BARRIER Coating chromed objects prevents direct contact with chromium, reducing potential skin irritations.

- FOOD SAFETY When applied to plastic containers, it prevents chemical agents from migrating into food and beverages, thus extending shelf life.

- PACKAGING PROTECTION SILITEC Seal helps reduce plastic thickness in trays while maintaining high protective performance. It prevents oxygen penetration, preserving food freshness for longer periods.

SILITEC SEAL: technical specifications

| Gases Used: | Inert gases, silyl ethers, oxygen |

| TMax Process Temperature: | max. 60 °C |

| Thickness: | generalmente intorno a 1000 nm |

| Minimum Hardness: | 600 Hv (outer layer) |

| Biocompatibility: | Yes (Non-toxic) |

| Coating Type: | Amorphous modified quartz, a:SiOCH |

| Chemical Resistance: | Fully resistant to acids, alkalis, solvents, and UV rays |

| Color: | Transparent |

SILITEC Seal©: Advantages

SILITEC Seal© is a plasma coating with unique properties, making it ideal for various applications.

Key benefits of SILITEC Seal:

- Transparent protective coating

- CVD deposition with guaranteed adhesion through plasma grafting

- Effective barrier with reduced oxygen transmission rate (OTR)

- Advanced protection against atmospheric, chemical, and organic agents

- High homogeneity

- Bacteriostatic properties

- Fully biocompatible and environmentally friendly

Applications of SILITEC Seal ©

SILITEC Seal © can be used in a variety of industries, thanks to its versatility.

- Food industry:Barrier film to extend shelf life. Corrosion protection for sensitive components. Prevents contamination of plastic articles. Shields non-noble materials from extreme environmental conditions. Seals materials to prevent chemical release.

- Other Applications: Toys – Scratch and abrasion protection, hypoallergenic properties. Jewellery & Watches – Quartz-like appearance, prevents nickel allergies. Babycare – Avoids contamination of food and drinks from plastic materials.