For more information about LIPOCER© and how you can best use it, contact us!

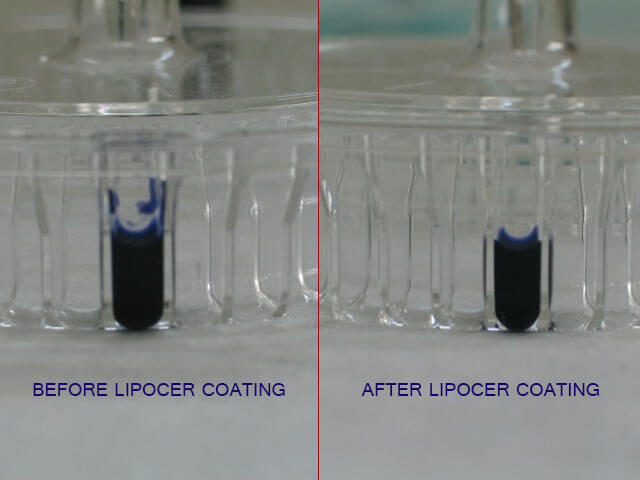

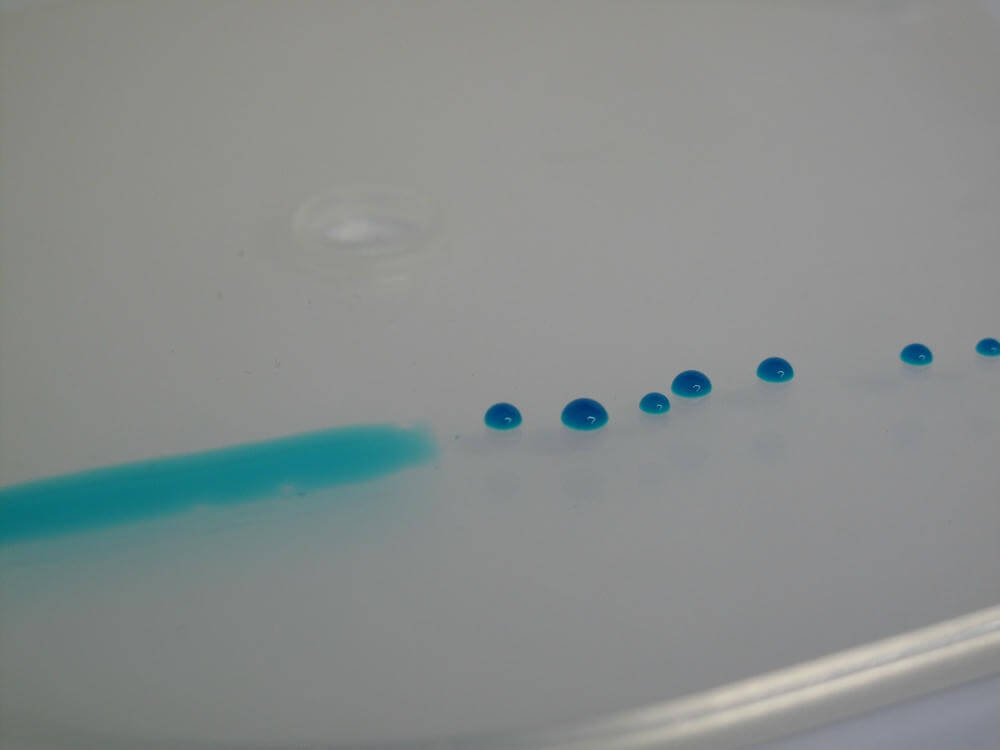

LIPOCER© is a permanent anti-sticking, hydrophobic, and PFAS-free treatment.

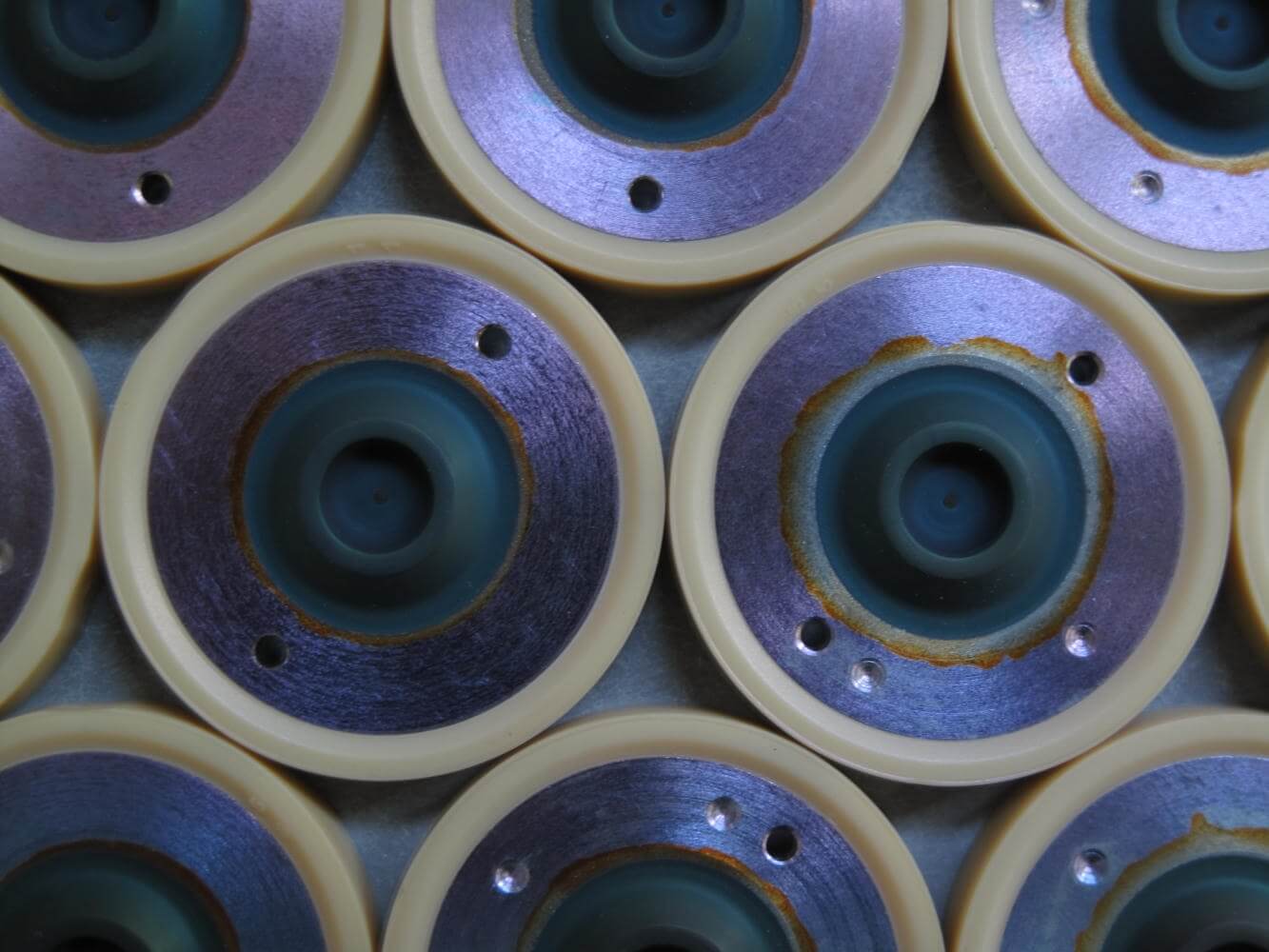

This anti-sticking coating is widely used on elastomers and rubber components to reduce friction, enhance sliding, and eliminate the stick-slip effect.

Appreciated for its excellent price-performance ratio, as well as its PFAS-free alternative, LIPOCER© is a homogeneous coating that significantly lowers surface tension and friction coefficient (COF).

It is a clean and highly effective solution for eliminating sticking issues and reducing friction.

On plastic and metal components, LIPOCER’s hydrophobic properties are highly valued, as they facilitate cleaning, prevent contamination, and reduce deposits.

How LIPOCER© Solves sticking issues

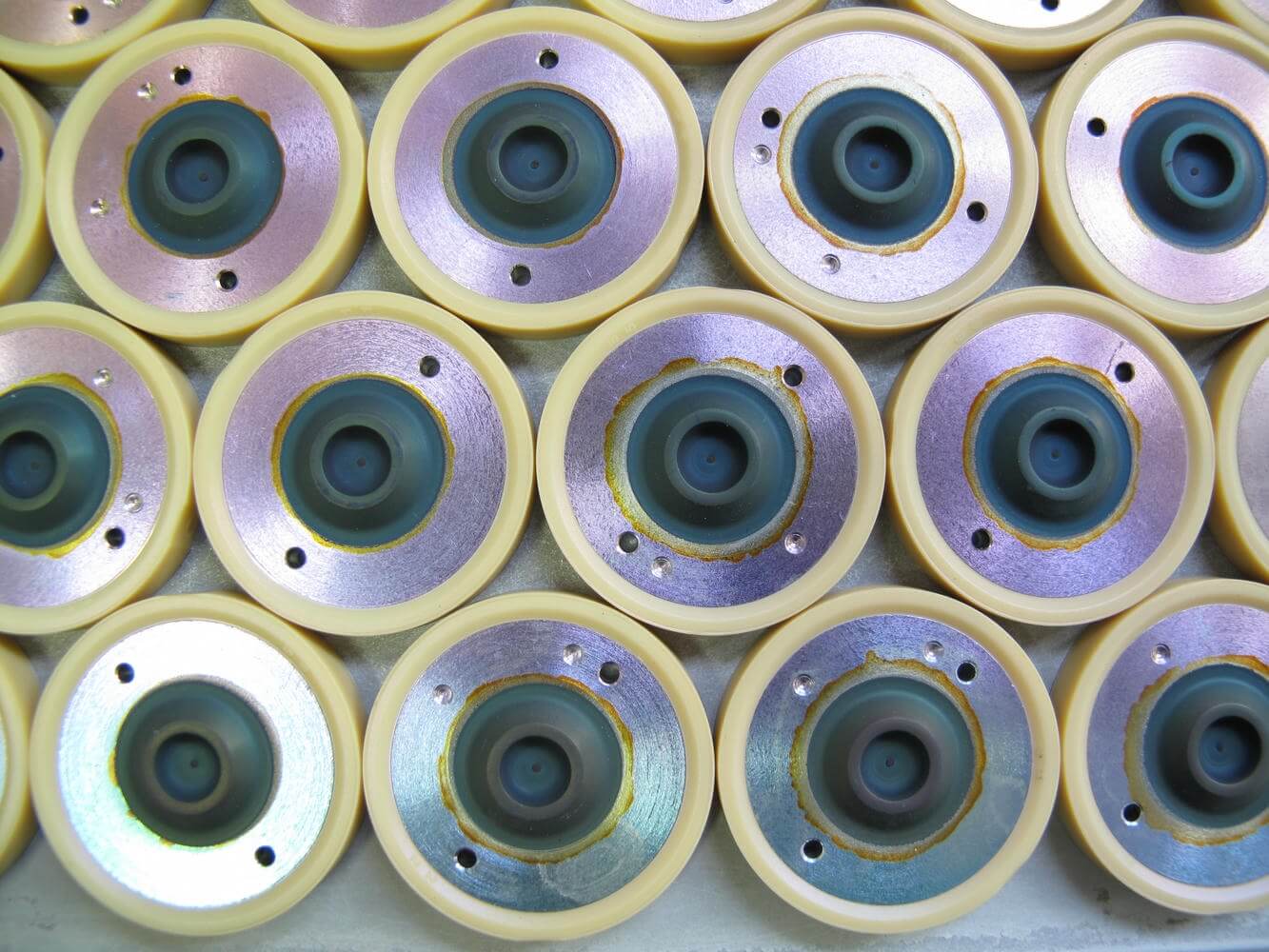

The sticking effect in rubber components (such as valves and seals) is caused by several factors, including:

- Microporosity of rubber

- Seal deformations

- Contamination and solvent absorption

- Exposure to corrosive gases

- Surface migration of rubber compounds

In all these cases, LIPOCER eliminates the sticking phenomenon, making it the most effective anti-sticking treatment in terms of performance, homogeneity, long-term stability, and surface adhesion.

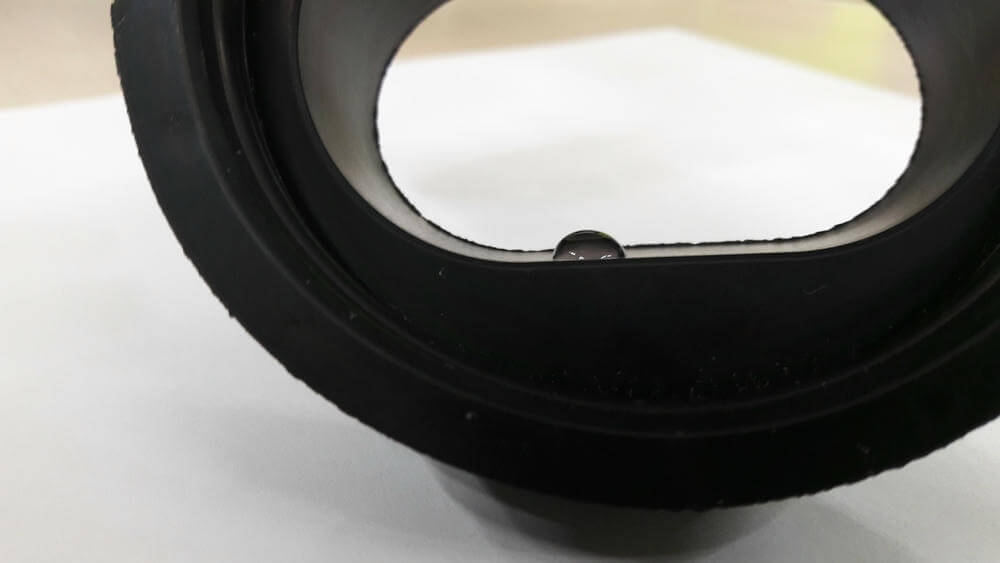

LIPOCER© & Stick-slip reduction

Due to its anti-sticking properties, LIPOCER also prevents the stick-slip effect, significantly reducing the force required to move shafts, pins, and valves, even after long periods of inactivity.

Even in extremely cold environments, valves and seals treated with LIPOCER continue to function smoothly and reliably, preventing sticking and blockage.

O-rings and axial seals slide more easily, experiencing less wear over time.

Customization & performance optimization

At Antec Finiture, we offer customized LIPOCER© treatments to meet specific application needs.

We can adjust key properties to ensure that anti-sticking effects do not interfere with other critical functions such as sealing performance.

Our expertise allows us to tailor LIPOCER© to a wide range of requirements:

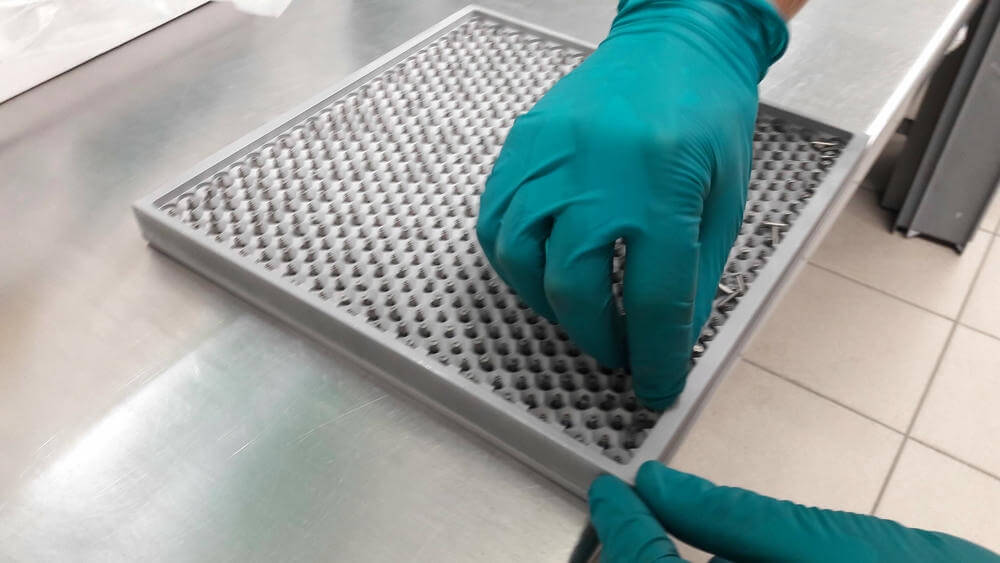

- For cost-sensitive applications, we optimize the treatment to facilitate sorting or automatic assembly.

- For more demanding applications, we ensure long-lasting and reliable anti-sticking effects without compromising sealing efficiency.

Plasma anti-sticking coatings: what sets LIPOCER© apart?

Not all anti-sticking coatings are the same.

The same treatment can be formulated differently, resulting in unique characteristics.

A key factor in achieving high-performance plasma coatings is proper positioning of coated components.

To achieve an efficient and effective plasma treatment, several parameters can be adjusted, including:

- Type & proportion of precursor gases

- Stoichiometry

- Deposition rate

- Power delivery

- Bias values

- Vacuum levels, and more

- And even more

A high-performance plasma treatment is not just a simple coating application, it is the result of years of expertise and technological innovation.

Antec Finiture has been offering PECVD coatings since 1999, leveraging decades of experience to provide the best possible solutions.

Lipocer: process data & technical characteristics

| Name: | LIPOCER © |

| Gases Used: | Ar, H2, O2 e HMDSO |

| Max Process Temperature: | 70 °C |

| Thickness: | compreso tra 30 nm e 500 nm |

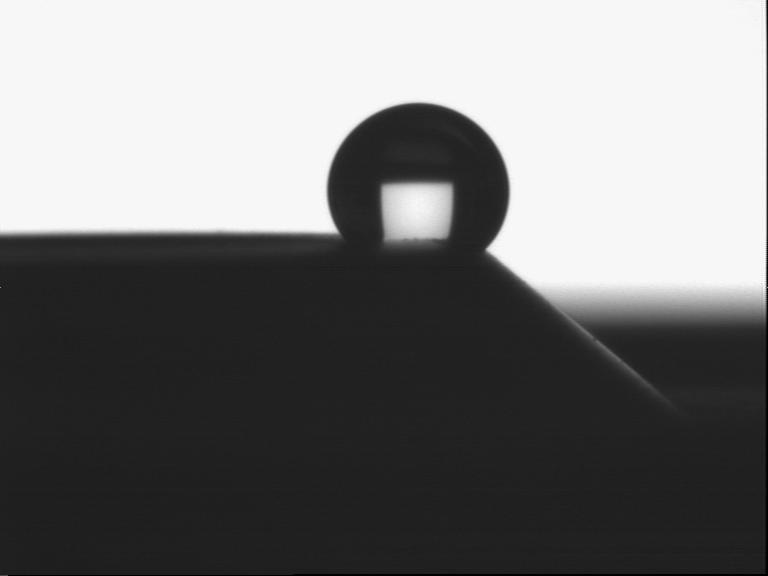

| Surface Tension: | < 30 mN/m |

| Coating Type: | Glassy Polysiloxane |

| Structure: | X-ray Amorphous |

| Coating Composition: | aSiCOH |

| Chemical Resistance: | Fully resistant to acids and bases |

LIPOCER©: advantages of the plasma coating

LIPOCER is a plasma-based coating with unique properties, offering multiple advantages:

- Precisely controlled thickness, from 30 nm to 500 nm.

- Ultra-low surface tension & low deposition temperature.

- Hydrophobic properties (water-repellent).

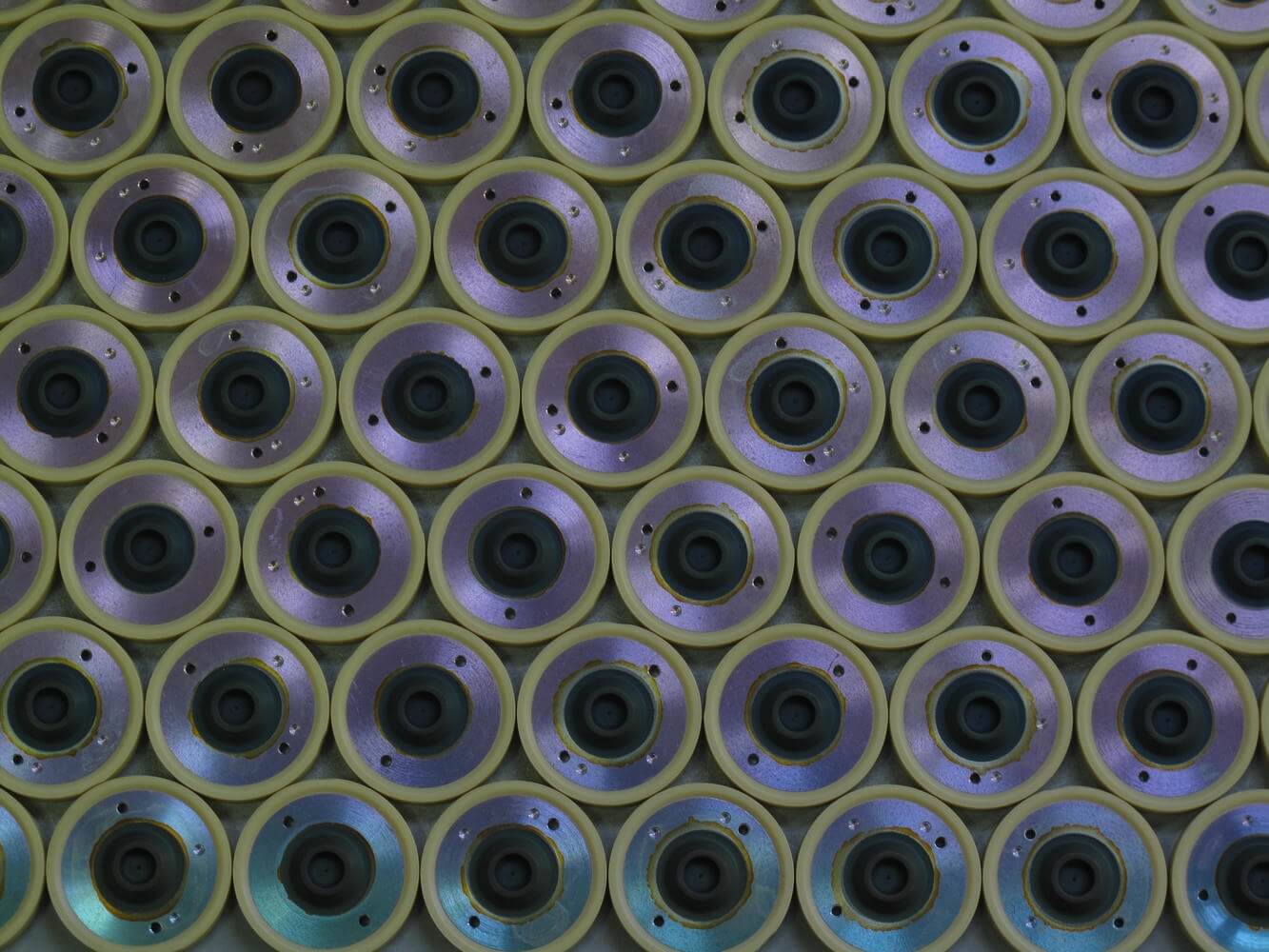

- Highly uniform & homogeneous coating.

- Preserves surface morphology & geometry.

- Exceptional anti-sticking performance.

- Outstanding chemical resistance.

- Biocompatible & compliant with health & environmental regulations.

- Protects polymer materials from UV exposure & chemical degradation, slowing aging.

LIPOCER©: industry applications

The LIPOCER anti-sticking coating is widely used across multiple industries due to its versatility.

Key Applications:

- Rubber & Elastomer Components: O-Rings, membranes, seals, rubber-metal overmolded parts, and technical rubber articles. Eliminates sticking & improves performance.

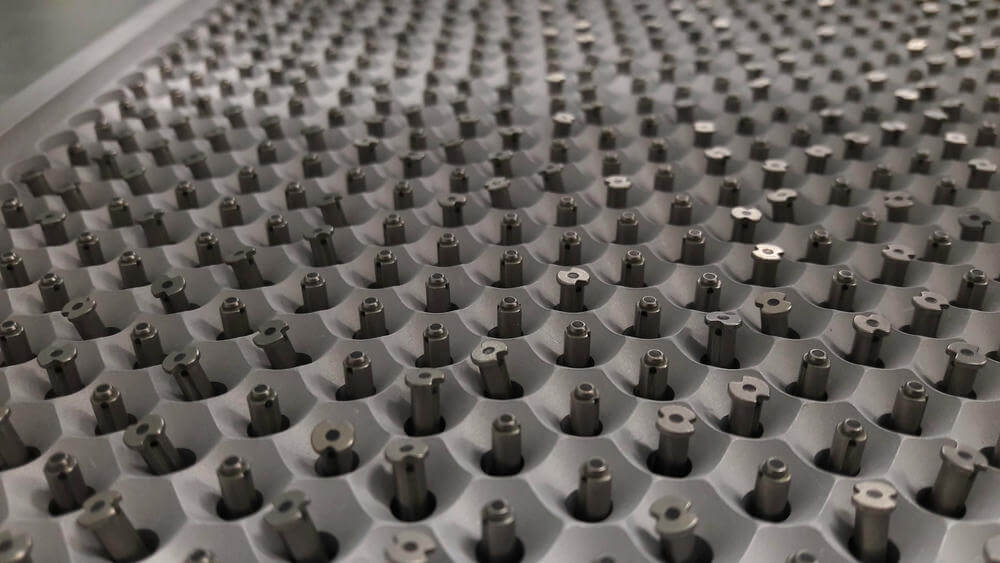

- Metal Components: Nozzles, needles, blades, and dosing systems.

- Automation & Assembly: Facilitates automatic gasket & rubber part assembly.

- Valves & Sealing Systems: o Reduces valve opening time & improves waterproofing of seals.

- Flow Regulators & Injection Valves: o Ensures smoother operation & long-term reliability.

- UV & Chemical Resistance for Gaskets: Maintains elasticity even after prolonged exposure to harsh environments.

- Medical Industry: Controls water contact angle, flow dynamics, and adhesion properties for precision applications.

LIPOCER© & anti-friction coatings: increasing reliability & performance

When combined with other anti-friction and anti-wear coatings, LIPOCER enhances the reliability of components, extending their lifespan and improving overall performance.

By reducing downtime and enhancing productivity, LIPOCER is a game-changer in industrial efficiency.