Attachments

Download our document to see specific data of the service and how we work.

For more information about DIATEC DECO and how you can use it effectively, contact us!

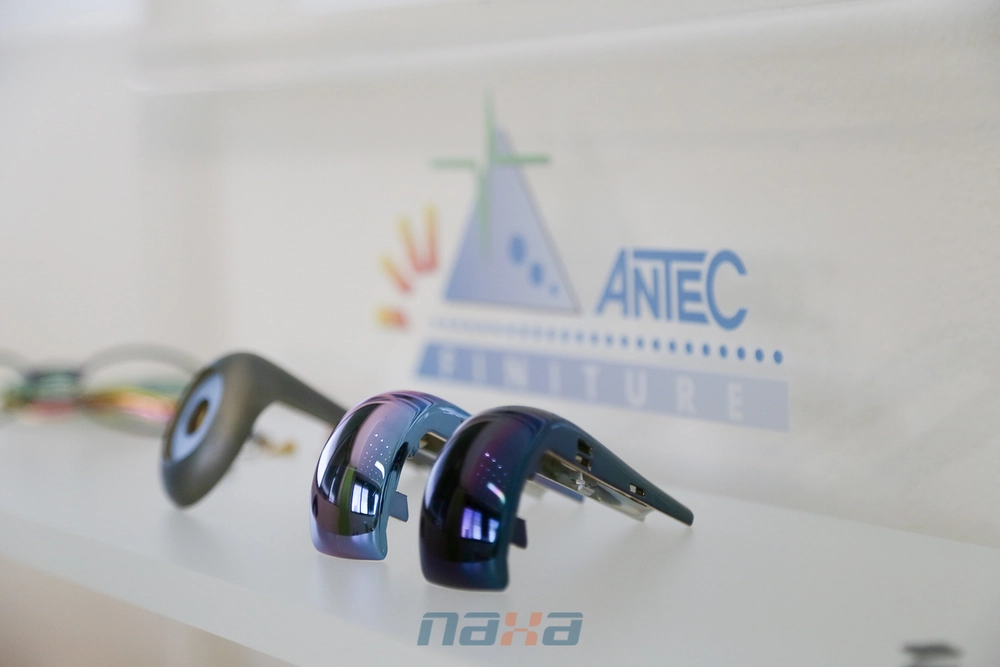

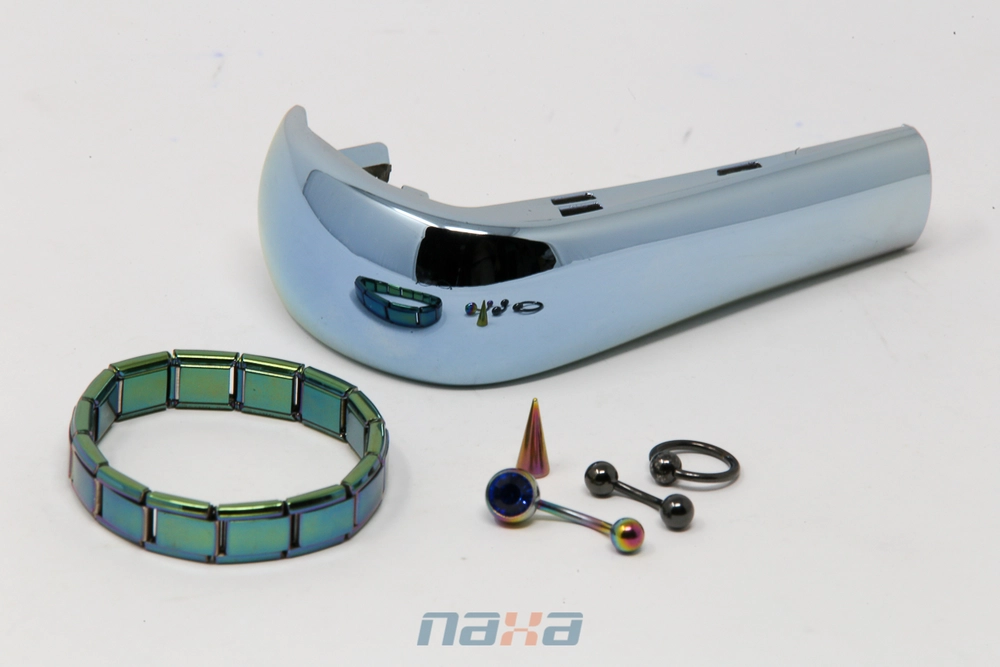

DIATEC Deco is a DLC (diamond-like carbon) coating primarily designed to give objects an eye-catching look. This amorphous carbon plasma coating, with iridescent shades in a predominant hue, offers exceptional physical properties, making it ideal for various industries.

Properties Of Diatec Deco Coating

- HARDNESS Thanks to the sp3 bonds that form the diamond structure and are abundant in DIATEC DECO, the coating can reach hardness levels of up to 1200 Hv.

- COLOR EFFECT DIATEC DECO provides a shimmering appearance, with dominant shades of BLUE, PURPLE, and RED, making objects stand out. Other hues like yellow and light blue are also possible, always shimmering due to light refraction and reflection phenomena.

- THERMAL STABILITY The DIATEC DECO coating can be applied at low temperatures (even below 100°C), while its thermal stability reaches up to 250°C.

- CHEMICAL RESISTANCE The chemical inertness of DIATEC DECO allows it to resist most acids and bases, making it effective even in aggressive environments.

- BIOCOMPATIBILITY & ENVIRONMENTAL FRIENDLINESS Diamond-Like Carbon is biocompatible, non-cytotoxic, hypoallergenic, and completely inert, making it ideal for medical and food applications. The deposition process is clean, free of harmful emissions, and at ANTEC, it is powered by green energy, guaranteed by in-house solar power production and certified suppliers.

An efficient DLC treatment is not simply the application of a basic substance, but the result of experience and expertise acquired over years of work. Antec Finiture S.r.l has been offering PECVD treatments since 1999. Our long-standing presence in the market is proof that we consistently provide the best solutions.

Technical Characteristics of the Treatment

| Commercial Name: | DIATEC Deco© |

| Max Process Temperature: | 100°C |

| Thickness: | 100 – 1000 nm (depending on the color) |

| Minimum Hardness: | 800 Hv |

| Surface Interference: | < 0.05 Ra |

| Thermal Stability: | Up to 250°C |

| Biocompatibility: | Yes |

| Type of Treatment: | a:CHSi |

| Structure: | X-ray amorphous |

| Chemical Resistance: | Unaffected by most acids and bases |

| Colors: | Shimmering Red, Purple, Blue, Light Blue, Yellow |

DIATEC DECO COATING: The Advantages

- Among decorative films, it is one of the most resistant to wear and abrasion.

- Adjustable internal stress and potentially flexible film.

- Resistant to atmospheric, chemical, and organic agents.

- Effective barrier against oxidation and corrosion.

- No alteration to surface roughness.

- Shimmering colors with dominant shades of RED, BLUE, PURPLE, LIGHT BLUE, or YELLOW.

Applications of DIATEC DECO

DIATEC is widely used across multiple industries, thanks to its versatility and high performance:

- Automotive ("carbon look", for innovative designs and long-lasting quality)

- Construction & Interior Design (facilitates cleaning, prolongs lifespan, prevents salt and limescale buildup, applied to faucets, mixers, and glossy black design objects).

- Hobbies & Sports (knives, fishing hooks, scuba regulators – providing an innovative look and protection against scratches and corrosion)