For more information about DIATEC and how you can best use them, contact us!

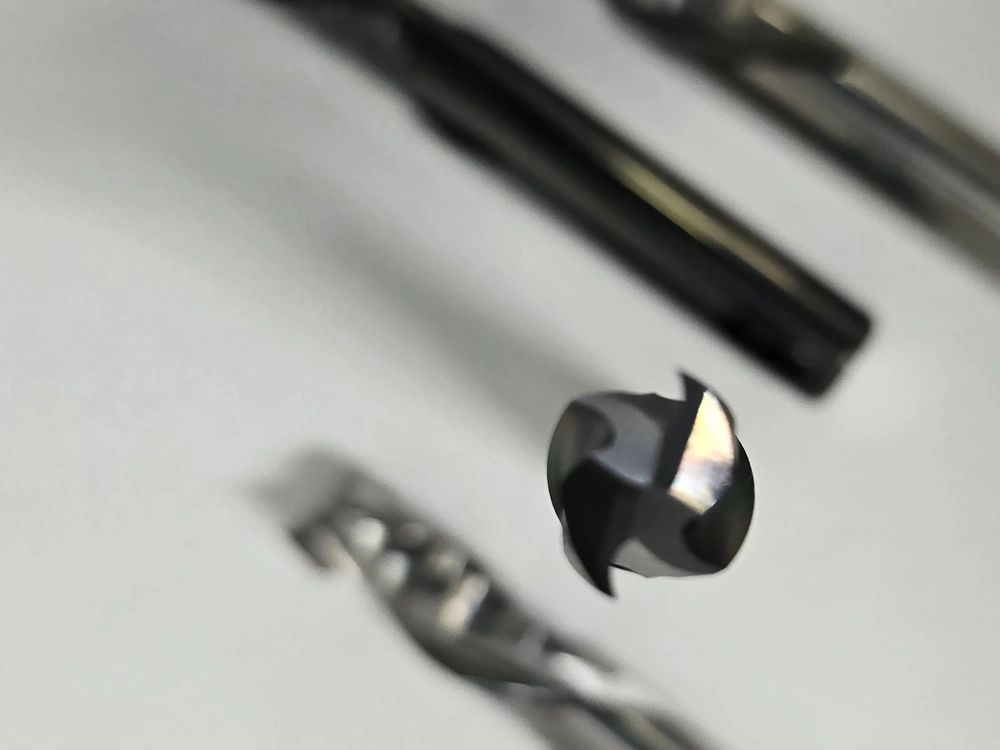

The DLC (Diamond-Like Carbon) treatment is a thin film highly valued in the market for many years.

This amorphous carbon plasma coating offers exceptional physical properties, making it ideal for multiple industries thanks to its low friction, high hardness, low deposition temperature, and strong chemical resistance.

DLC is a thin amorphous carbon deposit, combining diamond hardness with graphite smoothness, while being non-crystalline like diamond and not soft like graphite.

Deposition method

To obtain a DLC film, which we at Antec call DIATEC, objects undergo a vacuum plasma-assisted deposition process (PECVD).

A gas mixture, including hydrocarbons, is ionized to extract carbon, which is then deposited onto the object.

The deposition temperature can be controlled, ensuring it does not exceed 150°C, and adhesion is enhanced by creating an interlayer that chemically bonds the DLC film to the metal substrate.

Properties of DLC COATING

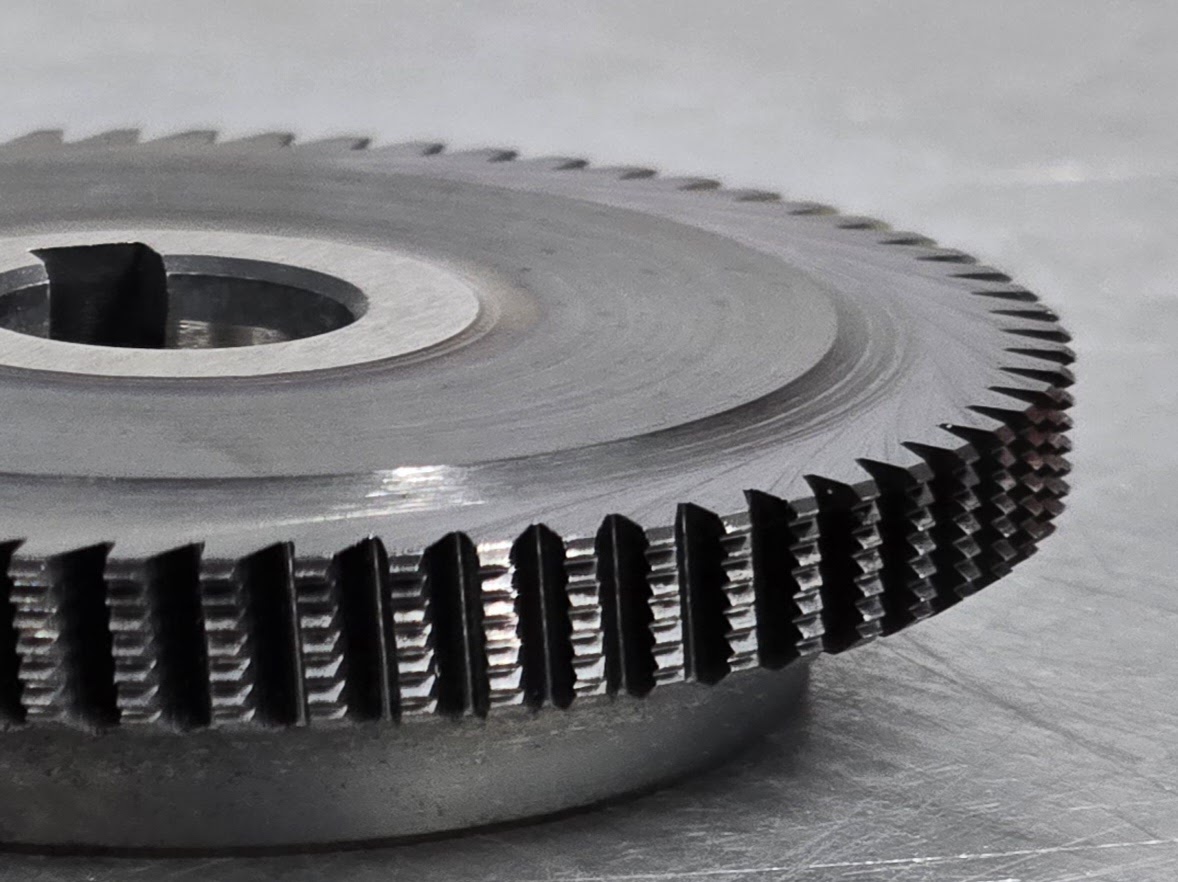

- HIGH HARDNESS: Thanks to its sp3 diamond-like bonds, DLC reaches very high hardness levels. With ANTEC's advanced processes, it is possible to achieve hardness values exceeding 2500 Hv, although these are only achievable on simple geometries and specific materials. For industrial production, where cost efficiency is a priority, the standard hardness typically reaches 2000 Hv.

- SELF-LUBRICATING Similar to graphite, DLC’s friction coefficient can reach as low as 0.04 under specific conditions. Since friction depends on multiple variables, achieving a low roughness is key. DLC further reduces friction, leading to less wear and a longer component lifespan.

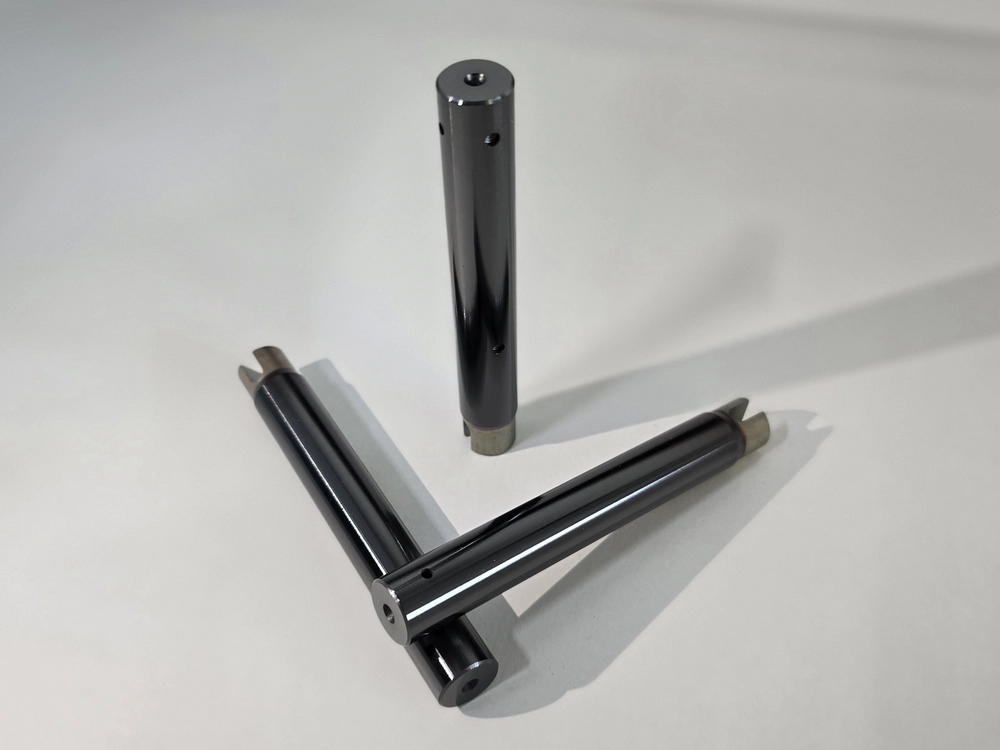

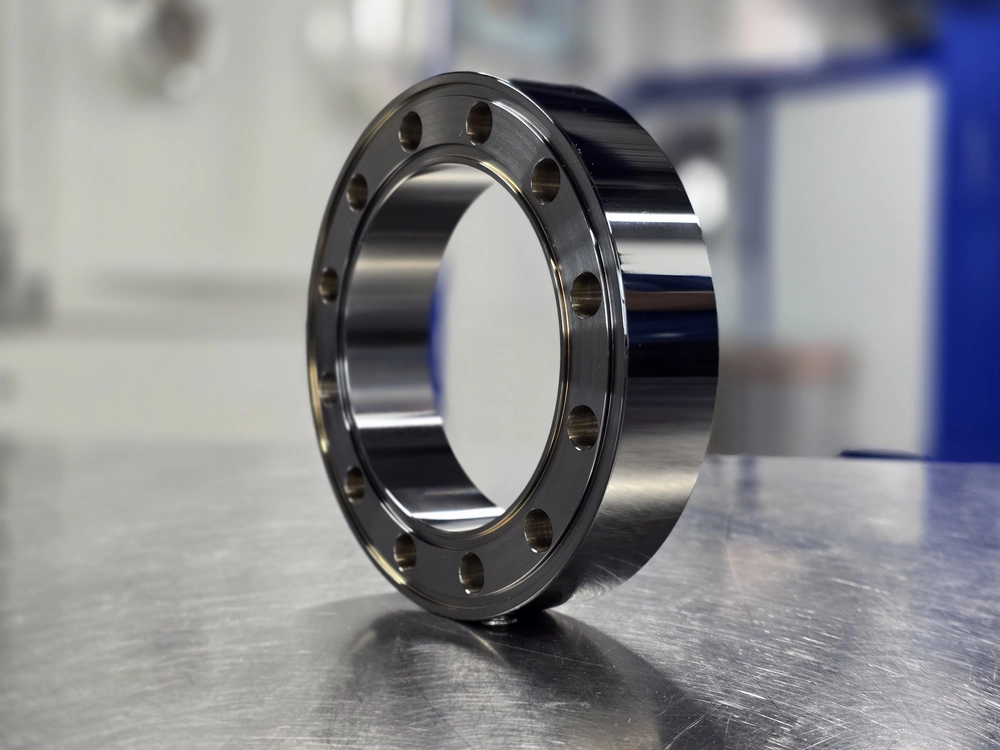

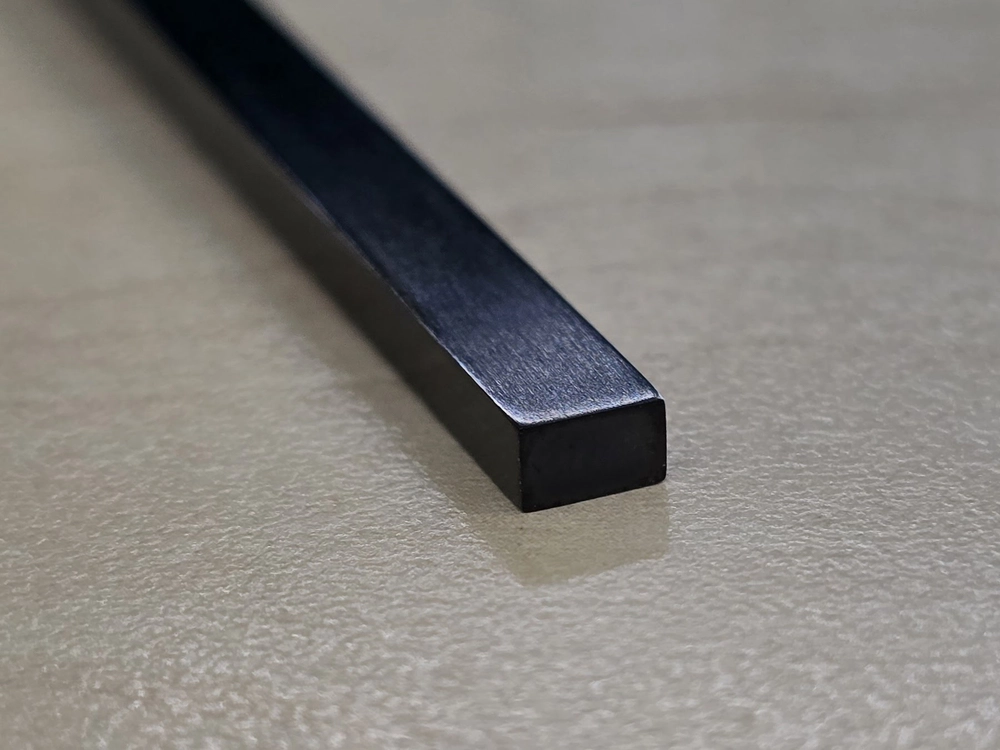

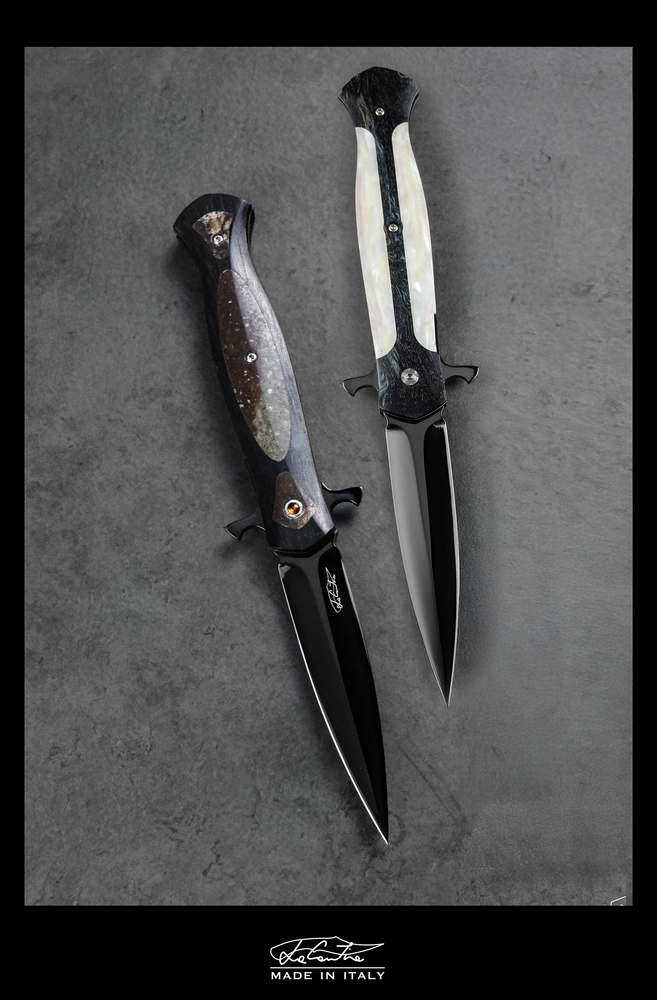

- TECHNICAL BLACK COLOR The black finish gives DLC-coated parts a technical, modern look, making the coating not only functional but also aesthetically appealing. This is why DLC treatment is commonly applied to fork tubes, knives, and high-end watches, where the black finish combined with scratch and wear resistance makes a significant difference.

- THERMAL STABILITY DLC coating can be applied at low temperatures (below 150°C) while maintaining thermal stability up to 350°C. Beyond this temperature, the coating tends to degrade.

- CHEMICAL RESISTANCE PECVD technology ensures a homogeneous coating, preventing oxidation and corrosion attacks. DLC’s chemical inertness allows it to resist most acids and bases, making it effective in aggressive environments.

- BIOCOMPATIBILITY & ENVIRONMENTAL FRIENDLINESS DLC is biocompatible, non-cytotoxic, hypoallergenic, and completely inert, making it ideal for medical and food applications. The deposition process is clean, free of harmful emissions, and at ANTEC, it is powered by green energy, sourced from solar power and certified suppliers.

Not all DLC coatings are the same. The same treatment can be achieved using different technologies and processes, resulting in varying characteristics. The coated parts play a crucial role, and knowing how to position them in the chamber is the first step in achieving a high-quality result.

Once the parts are positioned, various parameters can be adjusted to create the DLC coating: the type and percentage of precursor gases, altering the stoichiometry; the deposition rate; the applied power and bias values; as well as vacuum levels and process temperature. These variations allow for different chemical and physical properties, enabling DIATEC to be optimally adapted to each specific application while always keeping costs in mind.

An efficient DLC treatment is not simply the application of a basic substance, but the result of experience and expertise acquired over years of work. Antec Finiture S.r.l has been offering PECVD treatments since 1999. Our long-standing presence in the market is proof that we consistently provide the best solutions.

Technical Features of the Treatment

| Commercial Name: | DIATEC© |

| Max Process Temperature: | 150 °C |

| Thickness: | da 500 – 4000 nm |

| Minimum Hardness: | Up to 2500 Hv |

| Friction Coefficient: | 0.04 ÷ 0,2 |

| Thermal Conductivity: | Approx. 100 W/mk |

| Surface Interference: | < 0,05 Ra |

| Thermal Stability: | Up to 350 °C |

| Biocompatibility: | Yes |

| Coating Type: | DLC, a:CHxxx |

| Structure: | X-ray amorphous |

| Chemical Resistance: | Unaffected by most acids and bases |

| Color: | Anthracite/Black |

DIATEC: Available DLC Variants

At ANTEC, we offer three different DLC coatings:

- DIATEC HC: Our hardest DLC coating, best suited for technical applications.

- DIATEC Hybrid: A combination of DLC hardness with silicon’s barrier effect and elasticity, making it ideal for corrosion resistance and complex geometries where extreme hardness is not required.

- DIATEC Deco: Focused on aesthetic appeal, available in black and shimmering colors (blue, purple, red).